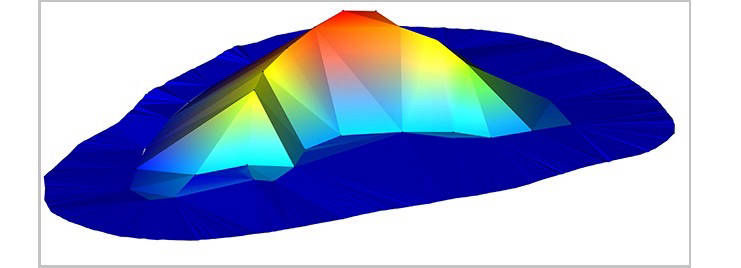

Figure 1: Example of surface output from “Traditional” survey methods (Stockpile comparision RTK)

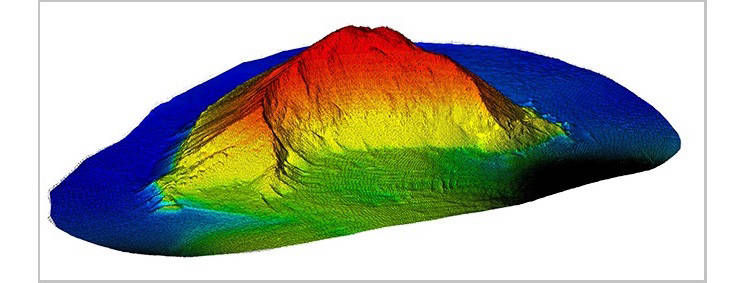

Figure 1: Example of surface output from “Traditional” survey methods (Stockpile comparision RTK) Figure 2: Example of surface output from using 3D laser scanning (Stockpile comparision Scanning)

Figure 2: Example of surface output from using 3D laser scanning (Stockpile comparision Scanning)Measuring a stockpile volume using 3D Laser Scanner technology is by far the quickest and safest method available. Whether it's aggregate, coal, wood chips, asphalt or anything else you inventory, our lasers have the ability to measure to almost any surface without the need of a reflector.

Traditional methods require your crew to hold a prism pole and occupy areas of a large pile of material. This process can be time-consuming and sometimes dangerous. Some areas make using a total station and prism pole even impossible because of loose material that can cause safety hazards, not even mentioning lack of detail and poor results you can obtain.

Sometimes, arranging for aerial fly-over is expensive and you will typically have to wait days or even weeks for the results. Depending on the time of year, the service may not even be available due to severe weather conditions. Times are tough so the need for monthly inventory assessments is becoming a reality. Time to complete measurement for each pile will vary according to the shape and profile. Generating the quantity from the software is very fast with the density available. Normally, we generate the provisional report of each day. Thus you can expect to have the quantity on a daily basis.

Traditional surveying methods measure locations of significant features. The more complex the shape, the more survey points are needed, and the longer and more expensive the survey becomes. Often the best that can be done cost-effectively is one point every 5-10 metres. But not every stockpile is a simple cone-shaped pile. When surveying complex shapes like open-pit mines or mountains, the surveyed shape is reduced to a blocky approximation, as Figure 1 shows. Accuracy is quickly reduced.

Falcon.3D scan can take measurements at centimetre-level resolution – usually from only a small number of scan locations, selected for their visibility and safety. That makes Seis-Scan more efficient and far more accurate. The most complex shapes are truly being measured and the survey result is an accurate depiction in three dimensions, as Figure 2 shows. And that lets the asset owner really understand what they have to work with.

Laser scanning is a quick and easy method for calculating stockpile volumes, with OH&S benefits accruing by remote measurement of surfaces

The high level of detail captured leads to improved volume accuracy. When using matching surface registration, appropriate checks ensure accuracy of registration (e.g. visual analysis of data, especially with the interactive sectioning tool).

Falcon.3D Provides a model creation and volume calculation methods are easy to use. The same principles can be applied to density determination, allowing better understanding of the stockpile mass.

3D laser scanning allows precise volumetric surveys to be conducted in very short time frames. Point cloud data can be georeferenced and transformed into any coordinate system. Mesh models created from the point cloud constitute highly accurate representations of the scanned terrain, chamber or coal pile

Post-processing, modelling, volume and density determination

A topographic filter is used to thin the data and remove unwanted, obscuring overhead scan points. The filter grid size reflects the stockpile size and the level of detail required. Further manual deletion of unwanted points may still be needed. A topographic triangulation is then created, and the stockpile volume is calculated.

After determining the volume, the density is needed to calculate the weight of the material in the stockpile. Truck scanning can be used to determine material density. An empty truck tray is modelled for a base, then the material is scanned and weighed.

The density is calculated: D = W/V

Results are available quickly, including volume results, density readings and screen captures. Video output can also be generated for use in formal presentations

.

Below you can see images of As Built Surveys taken using Scanner Stations